Raglan has been building tankers since 1987. Our bulk tankers are the lightest trailers on the market today and are available in all sizes and configurations. The weight savings gained combined with our industry recognized quality and makes Raglan tankers the more profitable choice in dry bulk transportation.

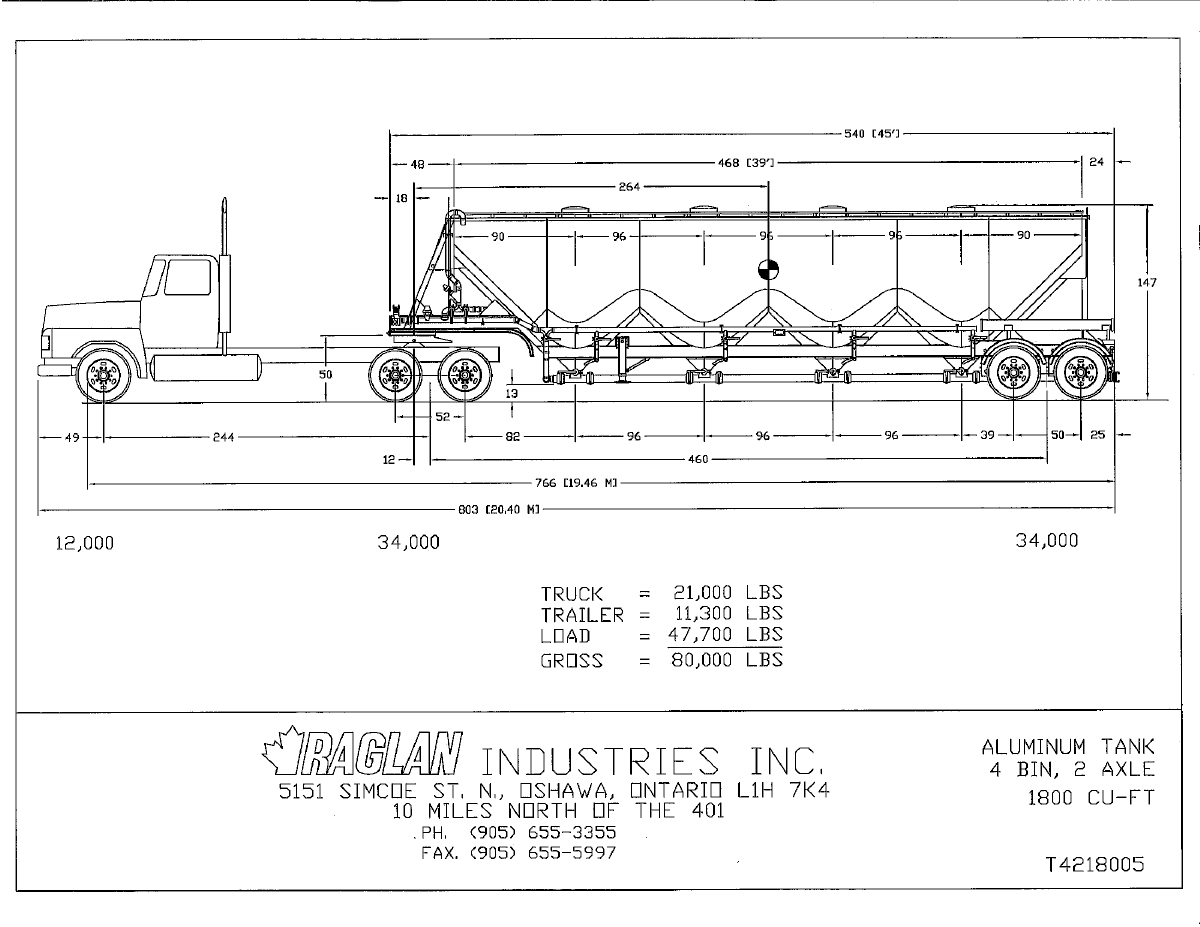

Length – 45’ 0”

Width – 102”

Height – 147” from top of manholes to ground level 13” ground clearance

Capacity – 1,800 ft3

Weight – 11,200 lbs.

Material – 22 5083 H-321aluminum plate, polished finish

The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1” aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Four (4) Knappco aluminum 20”, open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 9” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Axles – IMT 22,500 lb. straight spindle, 77 ½” track, inverted drop

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials, ContinentalHSR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum

Wheel Spacer – Wheel spacer guards between duals

Suspension – Raglan 25,000 lb. air ride, 50” spread tandem c/w manual dump valve

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting 3/8” plate @ 50” high c/w 18” king pin setting

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief @ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – One (1) 4” x 10’ rubber hot hose

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2” pressure relief @ 15 PSI and 3” blow off line

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½” line. (Aerators c/w rubberized stainless steel cone savers) No 2” flowbacks

Aeration – 30/30

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour

Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – – 8” x 20’ mounted curb side and 8” x 10’ mounted road side (hose not included), c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

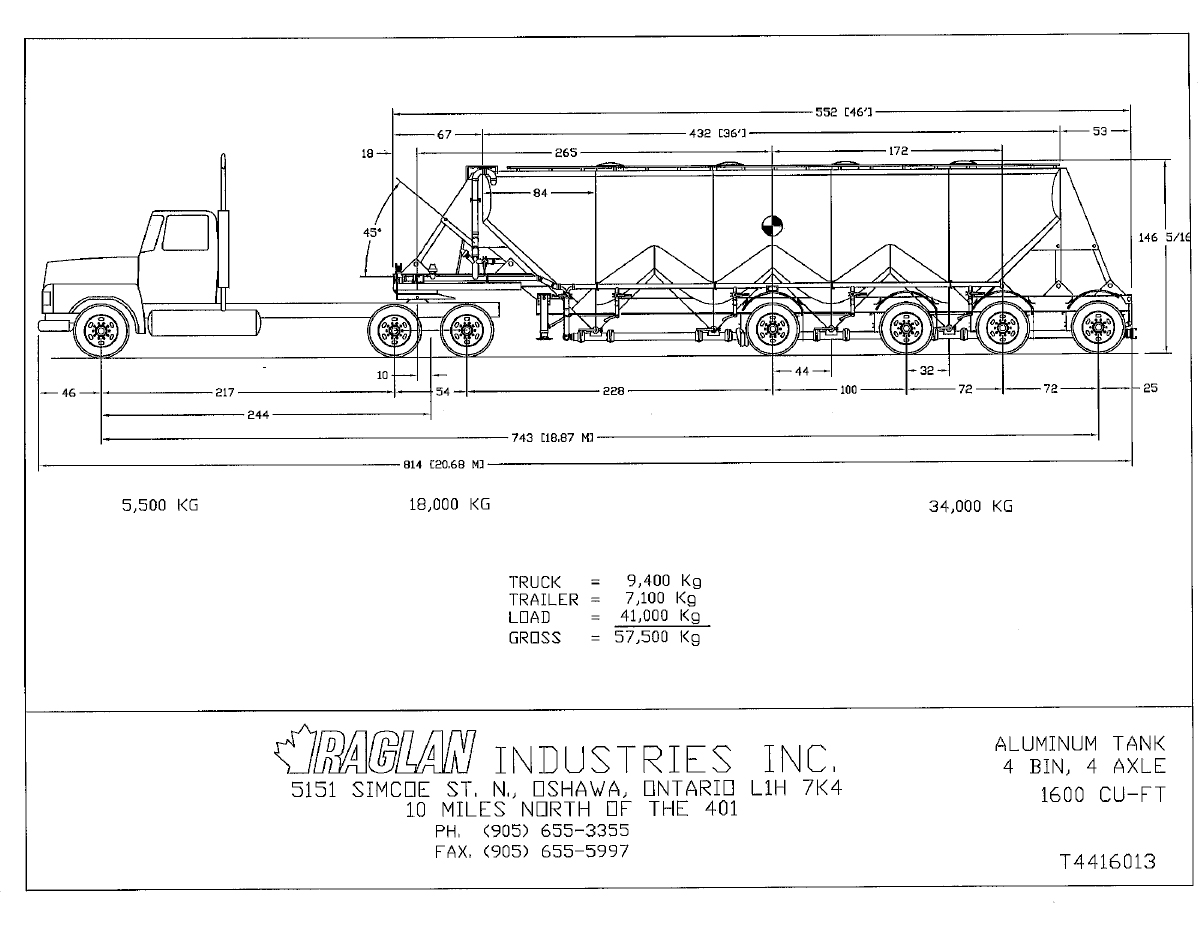

Length – 46’ 0”

Width – 102”

Height – 146 5/16” from top of manholes to ground level 12” ground clearance

Capacity – 1,600 ft3

Weight – 7,100 Kg.

Material – 22 5083 H-321aluminum plate, polished finish. The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1” aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Four (4) Knappco aluminum 20”, open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar. Raglan “Clean-cone” with bottom external flat bar stiffeners for no product hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 9” deep aluminum channel, full length of trailer. No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 72” spread tridem c/w manual dump valve

Lift Suspension – Raglan 25,000 lb. air ride @ 100” ahead

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Steering Axle – IMT 22,500 lb. straight spindle, 86” track inverted drop, 25° turn, reverse lock, reverse auto lift (RM-60)

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread) 385/65R 22.5 20 ply radials on steer axle, Continental HTR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum on tridem 12.25 x 22.5 10 hole hub pilot, Alcoa aluminum on steer axle

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting Upper coupler is bolted onto aluminum channel frame

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief @ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and coupler storage on road side

Hot Jumper Hose – One (1) 4” x 10’ rubber hot hose

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2” pressure relief @ 15 PSI and 3” blow off line

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap. The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½” line. (Aerators c/w rubberized stainless steel cone savers) No 2” flowbacks

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – 8” x 20’ mounted curb side and 8” x 10’ mounted road side (hose not included), c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

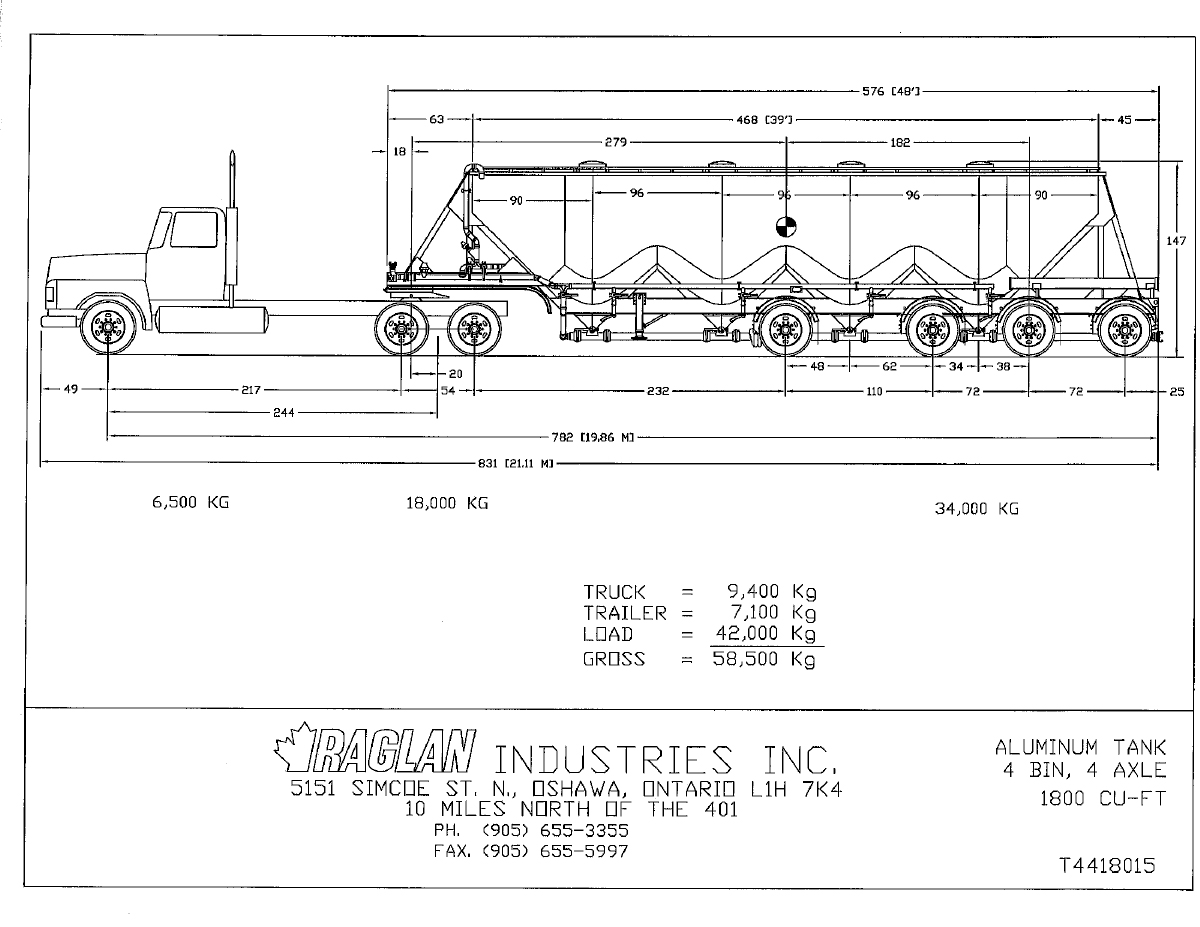

Length – 45’ 0”

Width – 102”

Height – 147” from top of manholes to ground level

Capacity – 1,800 ft3

Weight – 7,100 Kg.

Material – 22 5083 H-321aluminum plate, polished finish

The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1”

aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Four (4) Knappco aluminum 20”, open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product

hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 9” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 72” spread tridem c/w manual dump valve

Lift Suspension – Raglan 25,000 lb. air ride @ 100” ahead

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Steering Axle – IMT 22,500 lb. straight spindle, 86” track inverted drop, 25° turn, reverse lock,

reverse auto lift (RM-60)

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread)

385/65R 22.5 20 ply radials on steer axle, Continental HTR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum on tridem

12.25 x 22.5 10 hole hub pilot, Alcoa aluminum on steer axle

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting

Upper coupler is bolted onto aluminum channel frame

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief

@ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – One (1) 4” x 10’ rubber hot hose

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2”

pressure relief @ 15 PSI and 3” blow off line

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½”

line. (Aerators c/w rubberized stainless steel cone savers)

No 2” flowbacks

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank

pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front

of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour

Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – 8” x 20’ mounted curb side and 8” x 10’ mounted road side (hose not included),

c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

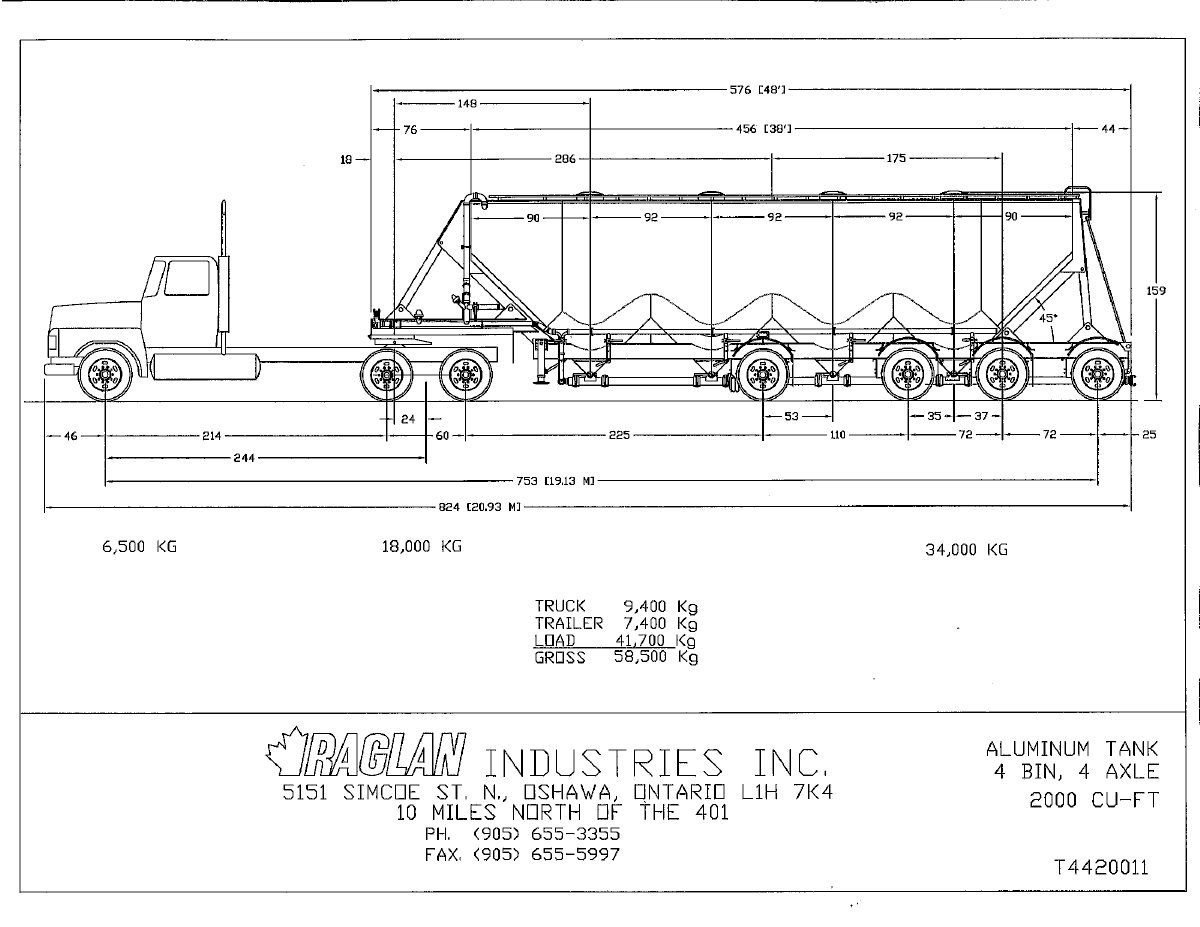

Length – 48’ 0”

Width – 102”

Height – 159” from top of manholes to ground level

12” ground clearance

Capacity – 2,000 ft3

Weight – 7,400 Kg.

Material – 22 5083 H-321aluminum plate, polished finish

The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1”

aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Four (4) Knappco aluminum 20”, open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product

hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 9” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 72” spread tridem c/w manual dump valve

Lift Suspension – Raglan 25,000 lb. air ride @ 110” ahead

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Steering Axle – IMT 22,500 lb. straight spindle, 86” track inverted drop, 25° turn, reverse lock,

reverse auto lift (RM-60)

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread)

385/65R 22.5 20 ply radials on steer axle, Continental HTR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum on tridem

12.25 x 22.5 10 hole hub pilot, Alcoa aluminum on steer axle

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting

Upper coupler is bolted onto aluminum channel frame

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief

@ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – One (1) 4” x 10’ rubber hot hose

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2”

pressure relief @ 15 PSI and 3” blow off line

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½”

line. (Aerators c/w rubberized stainless steel cone savers)

No 2” flowbacks

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank

pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front

of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour

Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – 8” x 20’ mounted curb side and 8” x 10’ mounted road side (hose not included),

c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

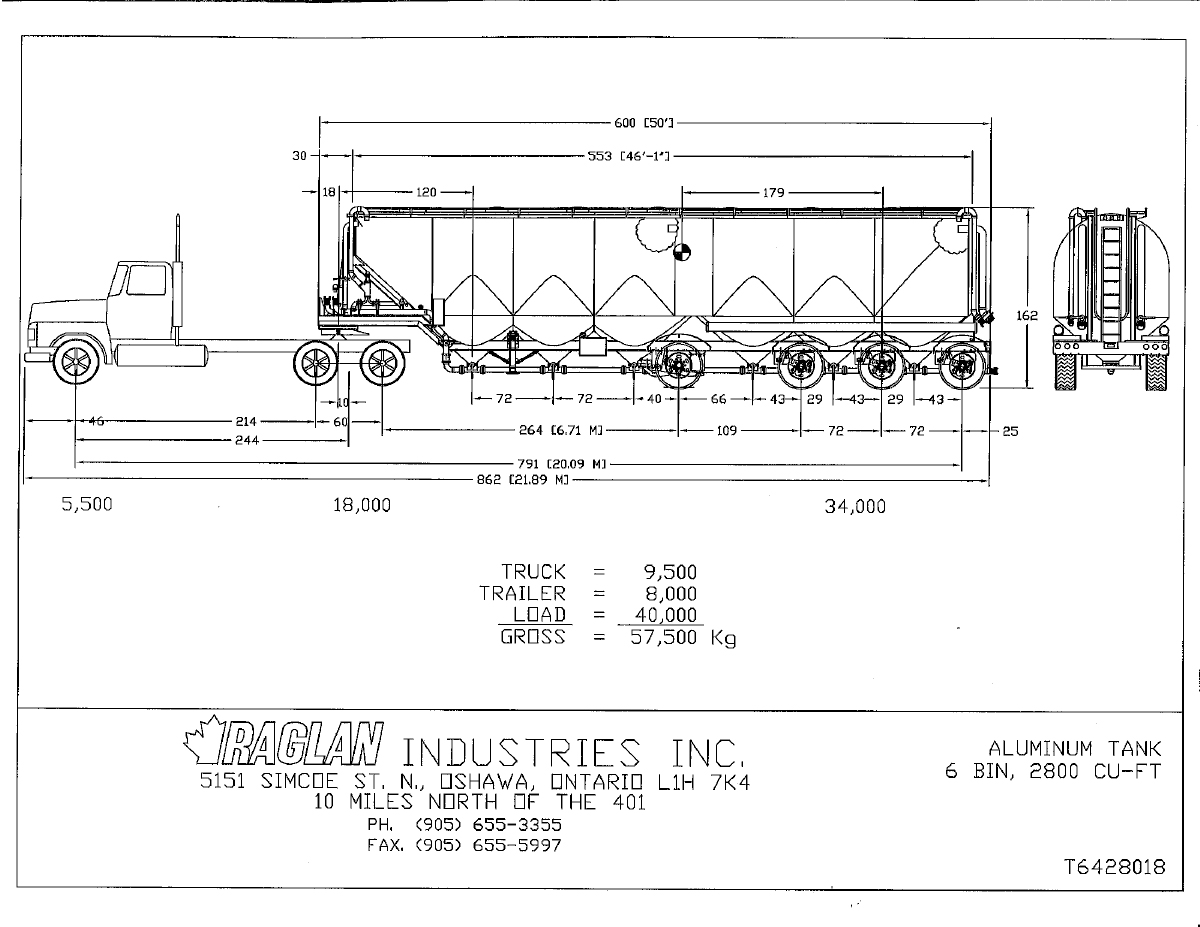

Length – 50’ 0”

Width – 102”

Height – 162” from top of manholes to ground level

12” ground clearance

Capacity – 2,800 ft3

Weight – 8,000 Kg.

Material – 22 5083 H-321aluminum plate, polished finish

The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1”

aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Six (6) Knappco aluminum 20”, open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product

hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 9” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 72” spread tridem c/w manual dump valve

Lift Suspension – Raglan 25,000 lb. air ride @ 109” ahead

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Steering Axle – IMT 22,500 lb. straight spindle, 86” track inverted drop, 25° turn, reverse lock,

reverse auto lift (RM-60)

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread)

385/65R 22.5 20 ply radials on steer axle, Continental HTR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum on tridem

12.25 x 22.5 10 hole hub pilot, Alcoa aluminum on steer axle

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting

Upper coupler is bolted onto aluminum channel frame

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief

@ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – One (1) 4” x 10’ rubber hot hose

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2”

pressure relief @ 15 PSI and 3” blow off line

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Filter – Interior mount Solimar, 24” Dia c/w 36” tubes

Vacuum Line – 4” from filter to front of tank

Vacuum Relief – Set at -15psi

Vent Line – 3” aluminum at rear

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/w aluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Aeration – Not required

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank

pressure, mounted at front and rear of trailer on drivers’ side c/w light, facing

the rear

Load Lines – Two (2) located at rear of tank, one loading to mid-point and one loading to rear

6” aluminum sch. 40 pipe, c/w female cam lock and plug

Lexan sight glass above valve

Food Grade – All valves, manholes, gaskets, Victaulic seals to be white rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front

of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – Two (2) 8” x 20’ tubes mounted one each side (hose not included), c/w cast

door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

Length – 48’ 0”

Width – 102”

Height – 160” from top of manholes to ground level

12” ground clearance

Capacity – 1,800 ft3

Weight – 8,100 Kg.

Material – 22 5083 H-321aluminum plate, polished finish

The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1”

aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Three (3) Knappco aluminum 20”, open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product

hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 9” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 72” spread tridem c/w manual dump valve

Lift Suspension – Raglan 25,000 lb. air ride @ 110” ahead, 110” spread

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Steering Axle – IMT 22,500 lb. straight spindle, 86” track inverted drop, 25° turn, reverse lock,

reverse auto lift (RM-60)

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread)

385/65R 22.5 20 ply radials on steer axle, Continental HTR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum on tridem

12.25 x 22.5 10 hole hub pilot, Alcoa aluminum on steer axle

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting

Upper coupler is bolted onto aluminum channel frame

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief

@ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – One (1) 4” x 10’ rubber hot hose

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2”

pressure relief @ 15 PSI and 3” blow off line

Discharge Line – – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½”

line. (Aerators c/w rubberized stainless steel cone savers)

No 2” flowbacks

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank

pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front

of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour

Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – 8” x 20’ mounted curb side and 8” x 10’ mounted road side (hose not included),

c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

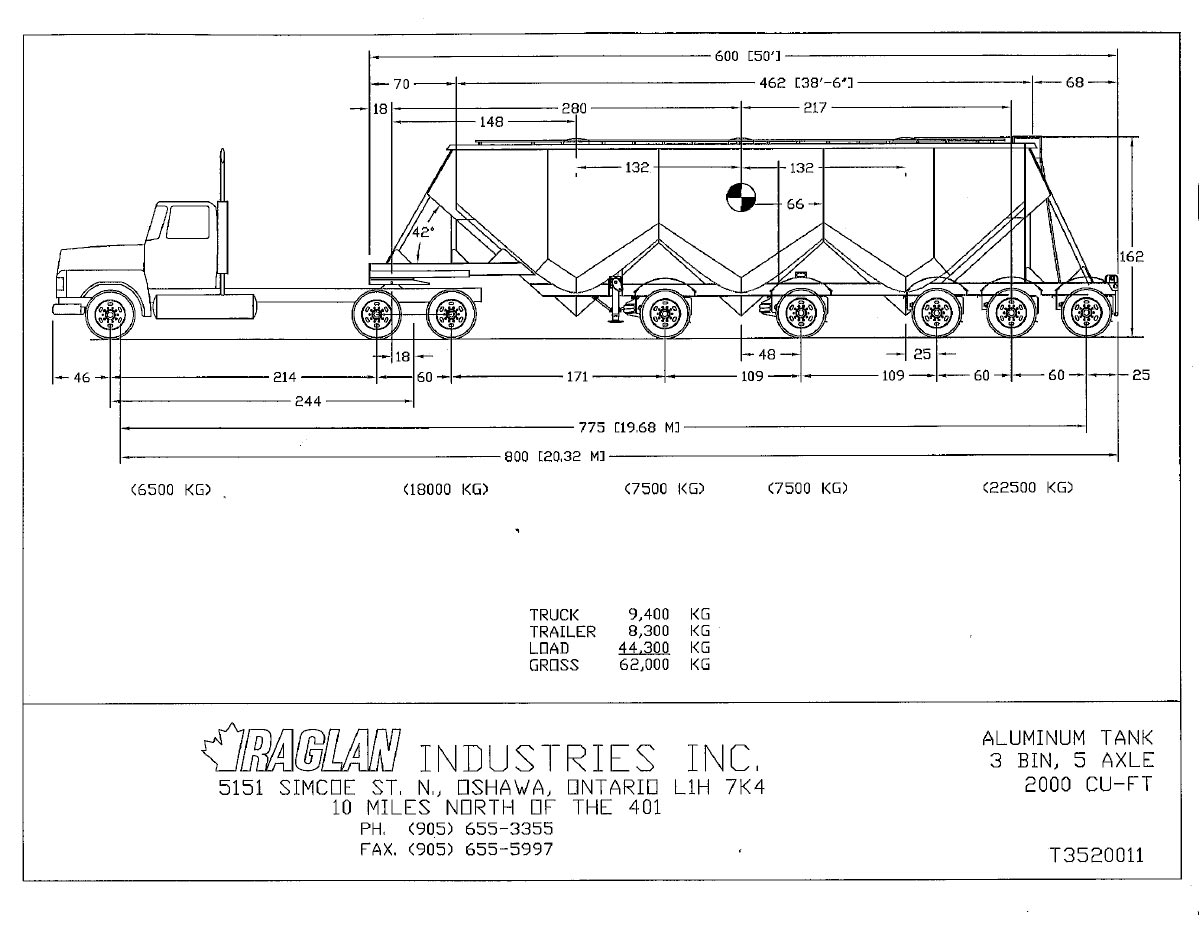

Length – 50’ 0”

Width – 102”

Height – 162” from top of manholes to ground level

12” ground clearance

Capacity – 2,000 ft3

Weight – 8,300 Kg.

Material – 22 5083 H-321aluminum plate, polished finish

The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1”

aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Three (3) Knappco aluminum 20”, open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product

hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 9” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 60” spread tridem c/w manual dump valve

Lift Suspension – Raglan 25,000 lb. air ride @ 109” ahead, 109” spread

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Steering Axle – IMT 22,500 lb. straight spindle, 86” track inverted drop, 25° turn, reverse lock,

reverse auto lift (RM-60)

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread)

385/65R 22.5 20 ply radials on steer axle, Continental HTR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum on tridem

12.25 x 22.5 10 hole hub pilot, Alcoa aluminum on steer axle

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting

Upper coupler is bolted onto aluminum channel frame

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief

@ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – One (1) 4” x 10’ rubber hot hose

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2”

pressure relief @ 15 PSI and 3” blow off line

Discharge Line – – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½”

line. (Aerators c/w rubberized stainless steel cone savers)

No 2” flowbacks

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank

pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front

of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour

Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – 8” x 20’ mounted curb side and 8” x 10’ mounted road side (hose not included),

c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

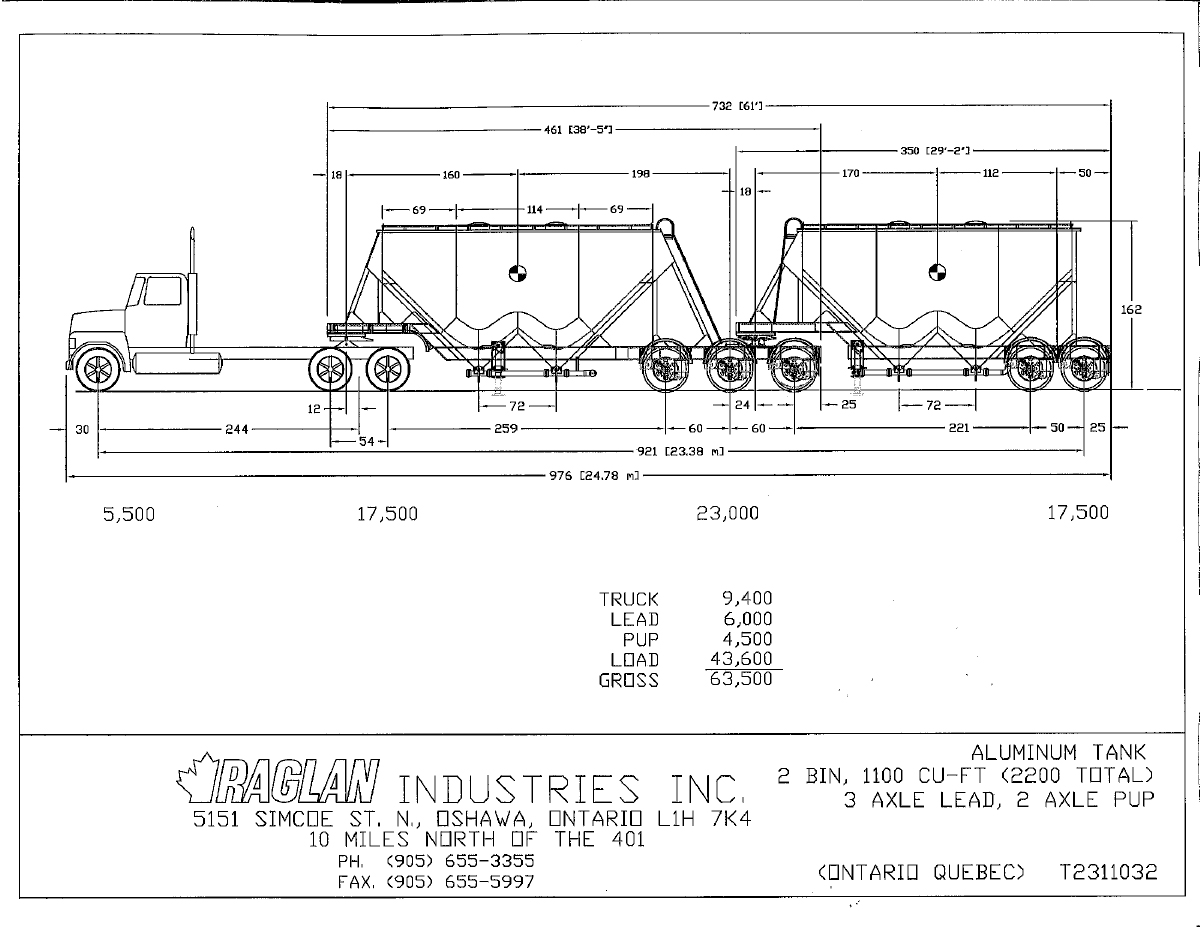

Length – 36’ 1” Lead and 28’ 6” Pup

Width – 1102” O.D

Height – 162” from top of manholes to ground

Capacity – 1,600 ft3

Weight – 9,100 Kg.

Material – 22 5083 H-321aluminum plate, polished finish

The tank is solid MIG welded

Ladder – Up rear of trailer with grip handles at top. Ladder is fabricated from 1”

aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – One (1) 20” Knappco aluminum , open toward front

Location as shown on drawing

Slope Angles – All slopes discharge @ 45°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product

hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 12” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 60” spread tridem on Lead, 50” tandem on Pup c/w

manual dump valve

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting

Upper coupler is bolted onto aluminum channel frame

Fifth Wheel Plate – Lead trailer has Holland 3500 Kompensator plate

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief

@ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – Two (2) 4” x 10’ rubber hot hose, one each on Lead and Pup

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2”

pressure relief @ 15 PSI and 3” blow off line

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Discharge Jumper – 4” dia. rubber hose c/w couplers on both ends, length to connect discharge on lead and pup

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½”

line. (Aerators c/w rubberized stainless steel cone savers)

No 2” flowbacks

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank

pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front

of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour

Aluminum washed natural polish finish

Control Box – Water-sealed, mounted on roadside of unit

Hose Tubes – 8” x 20’ mounted curb side and 8” x 10’ mounted road side (hose not included),

c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo

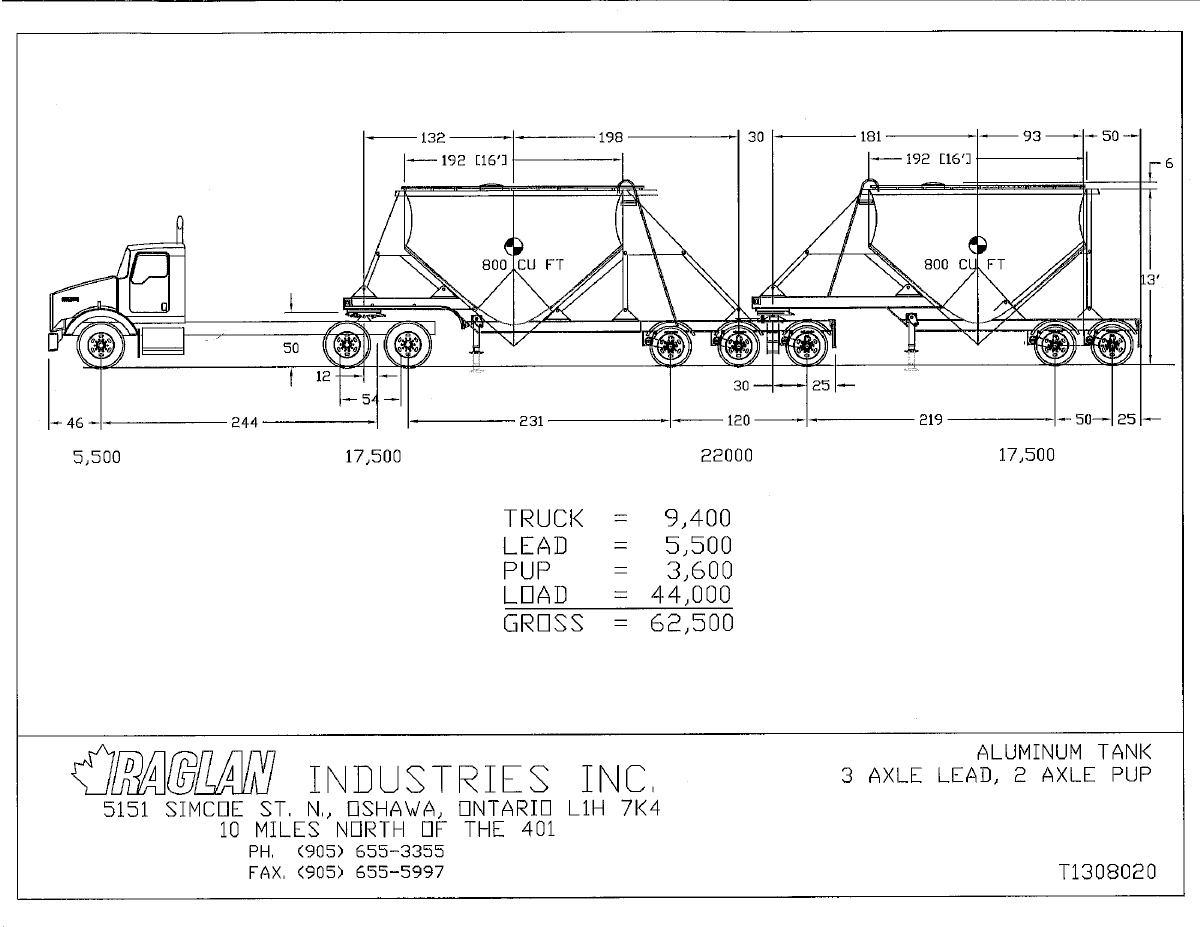

Length – 38’ 5” Lead and 29’ 2” Pup

Width – 102” O.D

Height – 162” from top of manholes to ground

Capacity – 2,200 cubic ft.

Weight – 10,500 Kg.

Material – 22 5083 H-321aluminum plate, polished finish. The tank is solid MIG welded

Ladder – Up rear of Lead trailer and front of Pup with grip handles at top. Ladder is

fabricated from 1” aluminum pipe c/w non-slip surface on the rungs

Cat Walk – No-slip surface on top of barrel, full length x 34” wide

Toe Kick – 4” high aluminum toe kick full length of barrel

Man Holes – Two (2) 20” Knappco aluminum, full opening toward front, each tank

Location as shown on drawing

Slope Angles – All slopes discharge @ 42°

Barrel Rings – Rings are internal 1/2” x 2 ½” rolled flat bar

Raglan “Clean-cone” with bottom external flat bar stiffeners for no product

hang-up

Safety Cable – 3/16” stainless steel cable, full length of barrel @ top, both sides

Frame – 12” deep aluminum channel, full length of trailer

No bolts or fasteners in gooseneck area

Braces – 3/8” x 4” x 4” 6061 aluminum extrusion from frame to top of barrel

All welded connections

Suspension – Raglan 25,000 lb. air ride, 60” spread tridem on Lead, 50” tandem on Pup c/w

manual dump valve

Axles – IMT 22,500 lb. straight spindle, 77 ½” track

Hubs – 10 stud steel

Lubrication – Oil

Brakes – 16.5 x 7 x ¾ Q-Brakes

Air Chambers – 30/30

Tires – 11R 22.5 16 ply radials on tridem, Continental HSR2 (highway tread)

Rims – 8.25 x 22.5 10 hole hub pilot, Alcoa aluminum

Wheel Spacer – Wheel spacer guards between duals

Landing Gear – Jost two speed with crank on driver’s side

Pick Up Plate – 3/8” plate @ 50” high c/w 18” king pin setting

Upper coupler is bolted onto aluminum channel frame

Fifth Wheel Plate – Lead trailer has Holland 3500 Kompensator plate

ABS – Haldex 2S/1M

Air Tanks – Rubber mounted aluminum, all with manual pull drains

Bumper – Fabricated aluminum at rear of unit

Hot Air – 4” O.D. diameter pipe c/w swivel adapter, 4” flow back, and 2” pressure relief

@ 18 PSI. Hot air pipe has a 90º elbow at front of trailer, c/w hose hook and

coupler storage on road side

Hot Jumper Hose – Two (2) 4” x 10’ rubber hot hose, one each on Lead and Pup

Top Air – 3” O.D. diameter aluminum pipe to top of tank at rear c/w 3” butterfly valve, 2”

pressure relief @ 15 PSI and 3” blow off line

Discharge Line – 4” sch. 40 aluminum discharge line running through to rear of trailer, c/waluminum adapter and cap

The discharge has B.T.I. All-In-One Victaulic Couplers between the discharge

valves of each bin

BTI aluminum 6” x 4” Siphon Flow Discharge Ts

Discharge Valve – 6” butterfly valve (B.T.I.) complete with handle extension to road side

Discharge Jumper – 4” dia. rubber hose c/w couplers on both ends, length to connect discharge on lead and pup

Aeration – Three (3) B.T.I. aerators mounted on each cone c/w 2” butterfly valve and 1 ½”

line. (Aerators c/w rubberized stainless steel cone savers)

No 2” flowbacks

Gauges – 4” diameter glycerin filled 0-30 PSI, one (1) for line pressure, one (1) for tank

pressure, mounted on drivers’ side c/w light, facing the rear.

Valves – BTI, composite body, steel disc, black rubber

Lights – L.E.D. c/w side signals

Fenders – Nu-Line aluminum contoured over each axle and flat aluminum fenders at front

of trailer over tractor drive axles

Flaps – Mounted on each fender

Finish – All steel components sandblasted, primed, and painted one (1) colour

Aluminum washed natural polish finish

Hose Tubes – 8” x 20’ and 8” x 10’ (hoses not included) mounted on Pup, c/w cast doors and lids

8” x 4’ jumper tube mounted under Pup frame, c/w cast door and lid

Interior – Professional cleaning is recommended prior to use to avoid possible

contamination of cargo